2025-12-26 IntroductionCreating a stunning river table is an investment of both time and expensive timber. However, for many artisans and furniture studios, the skyrocketing cost of retail-branded epoxy resin has become a major hurdle to profitability.If you are buying 1-gallon kits from Amazon or local craft

Read More

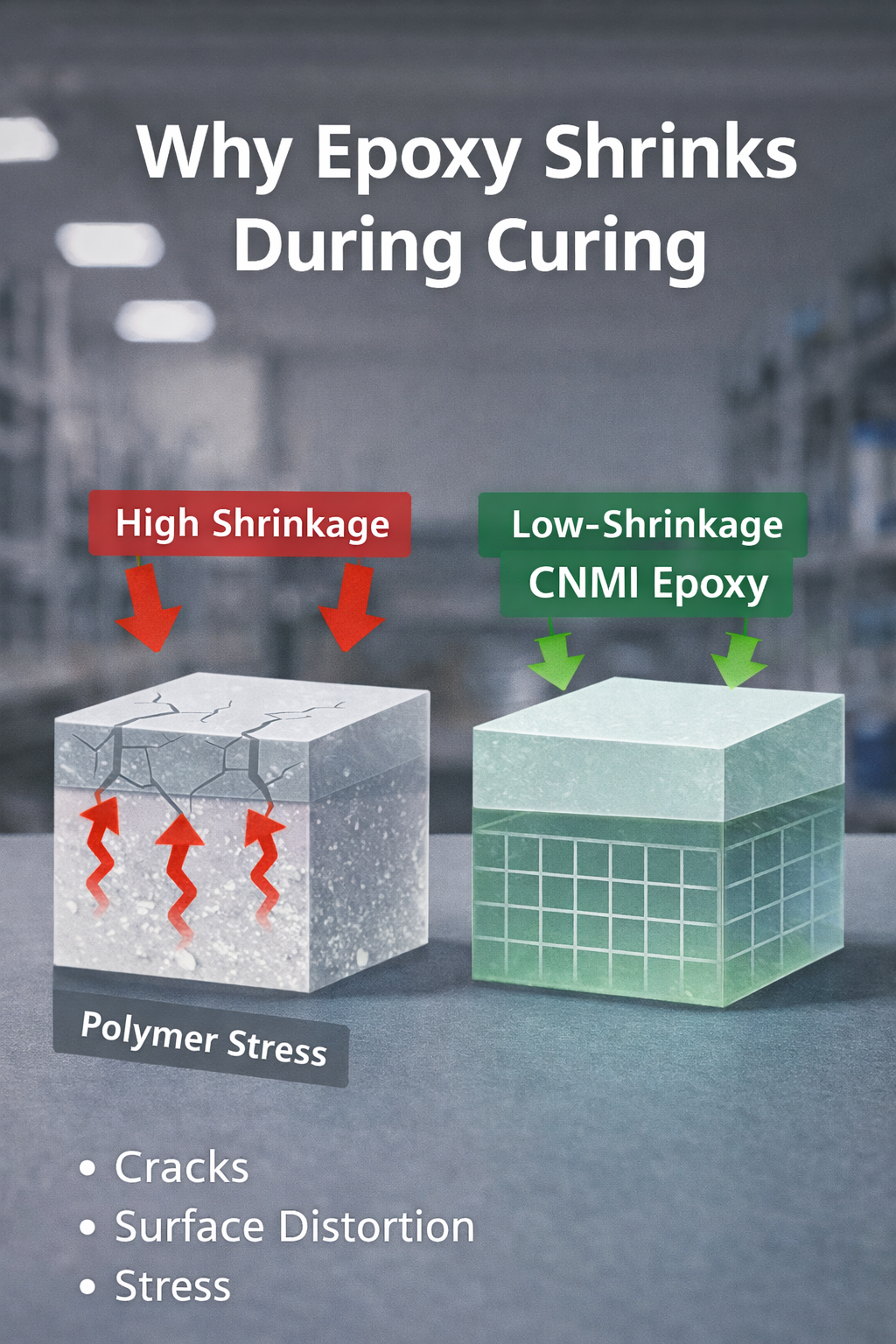

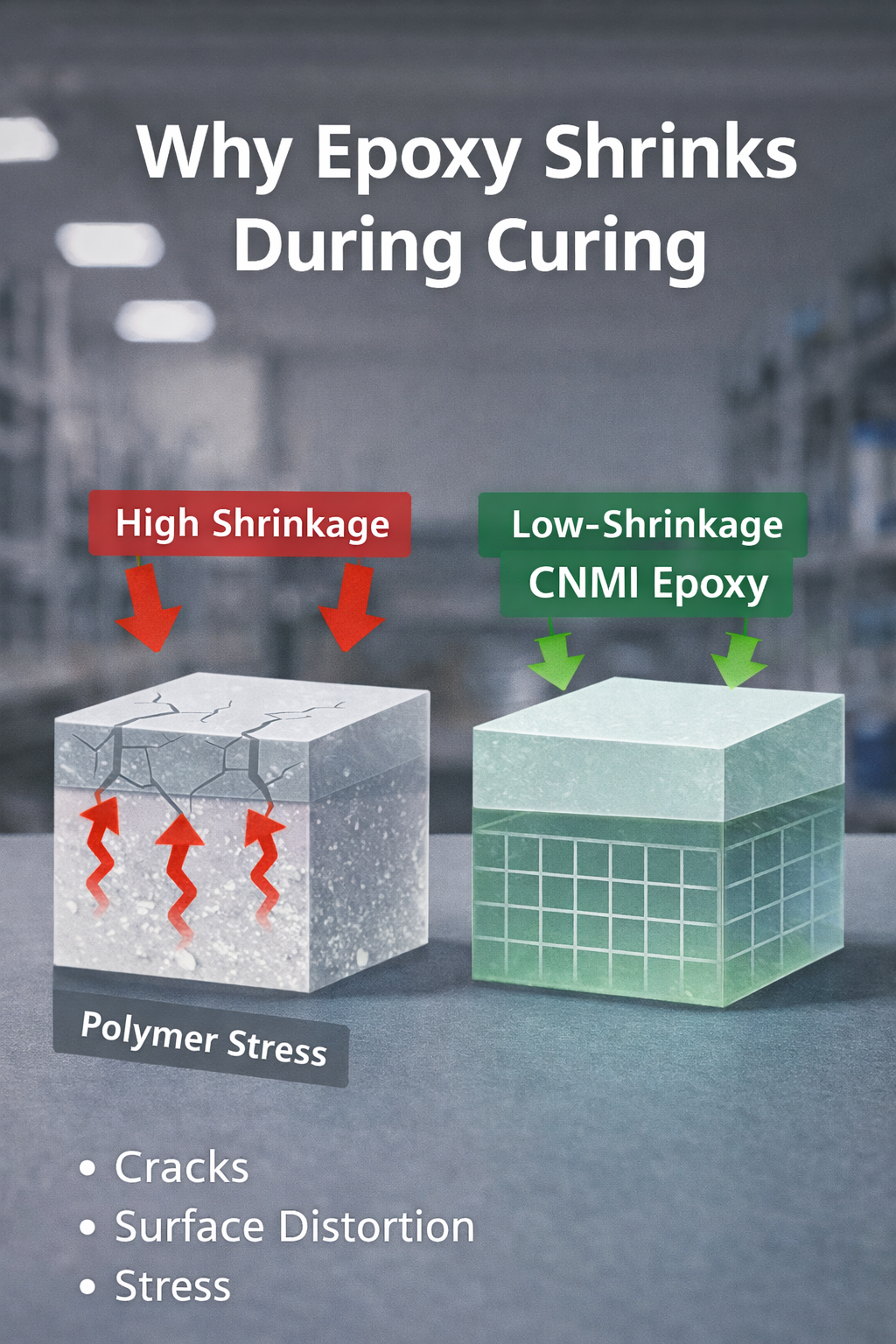

2025-12-17 Epoxy resin is valued for its strength, clarity, and durability—but like all thermosetting polymers, epoxy undergoes shrinkage during curing. While often subtle, shrinkage can lead to visible defects, internal stress, surface distortion, or long-term performance issues if not properly controlled.At

Read More

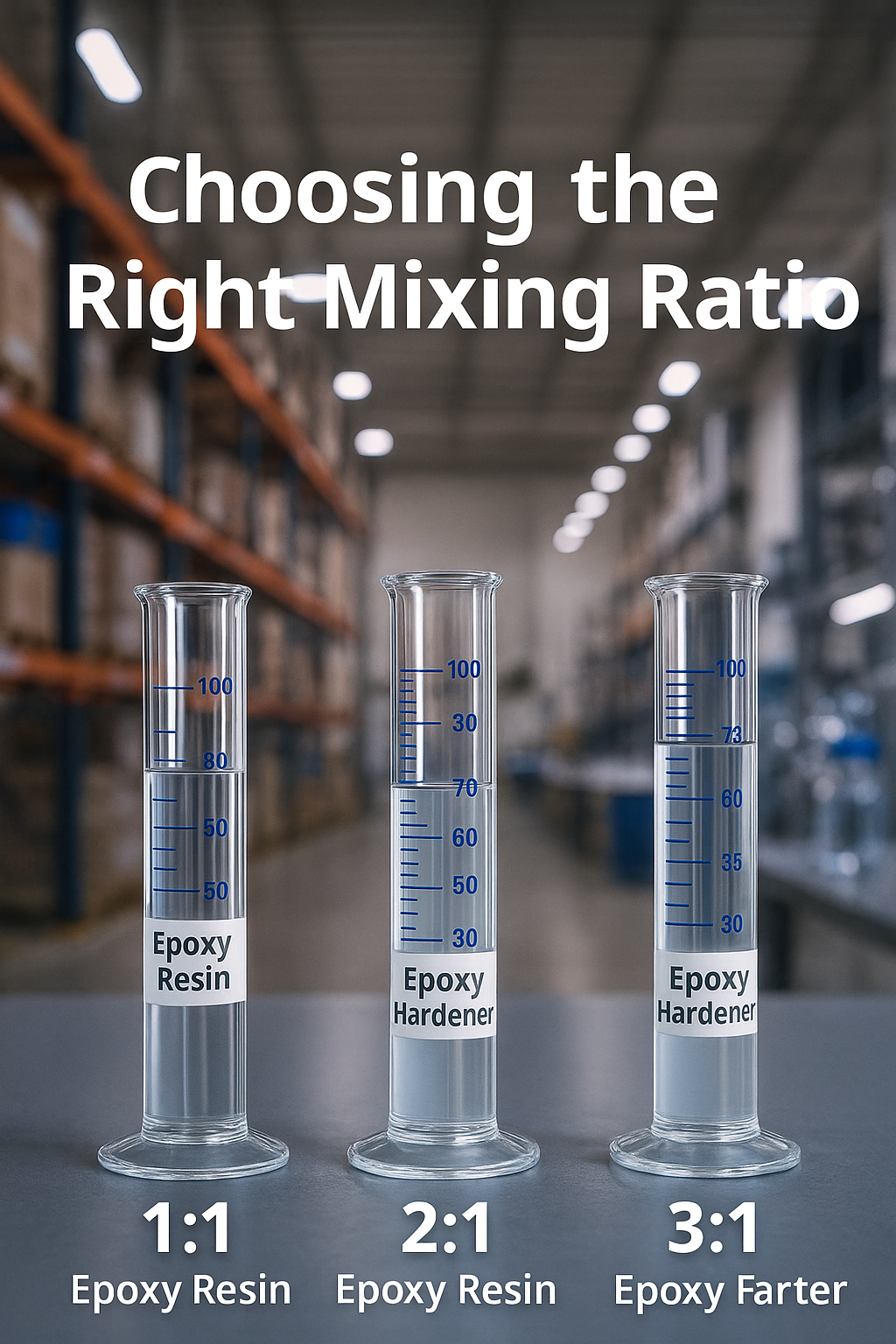

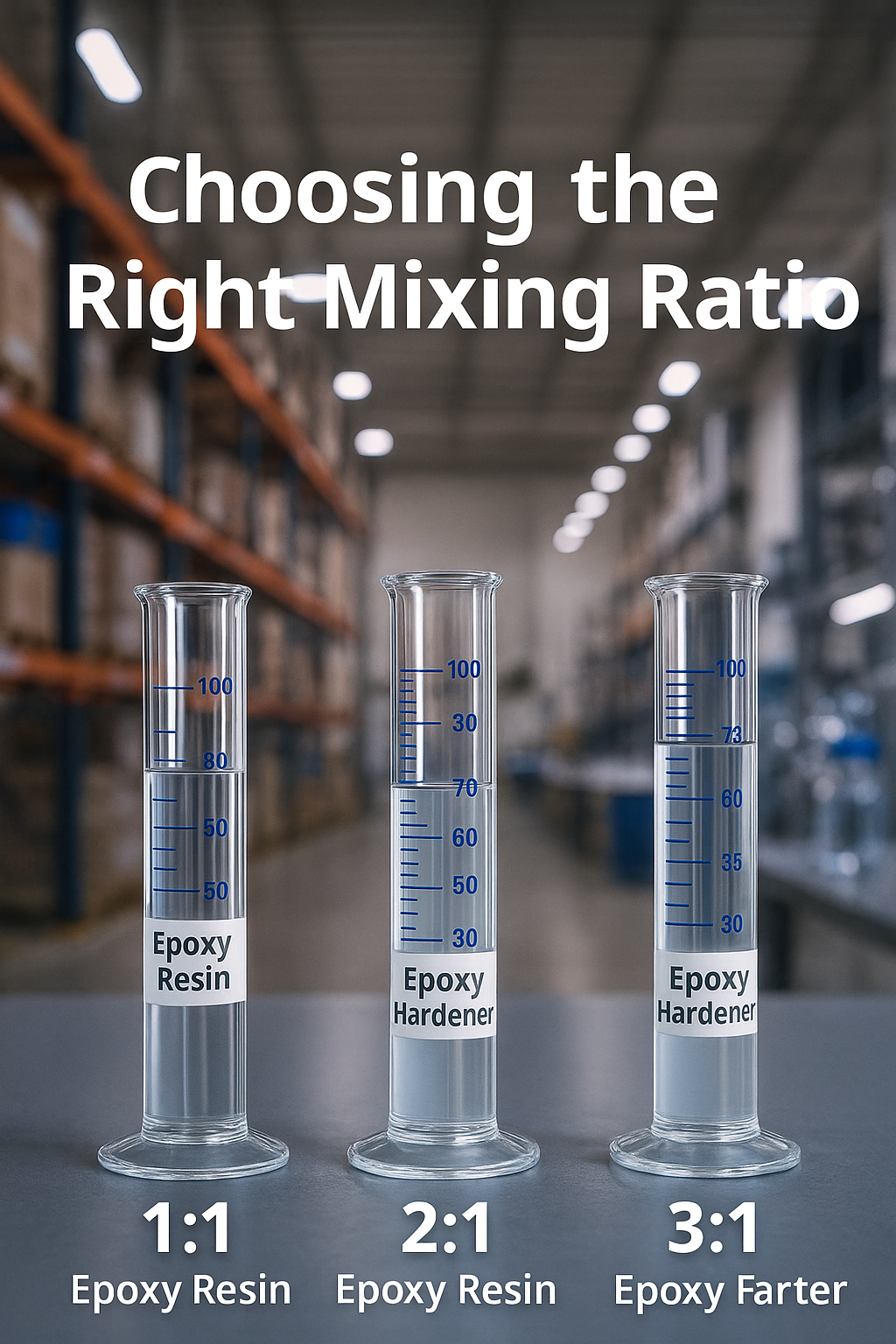

2025-12-10 With so many epoxy resin systems available today, users often ask a critical question:➡ What is the difference between 1:1, 2:1, and 3:1 epoxy ratios—and how do you choose the right one?Mixing ratio plays a major role in performance, clarity, workability, and strength. At CNMI Industrial Corporation

Read More

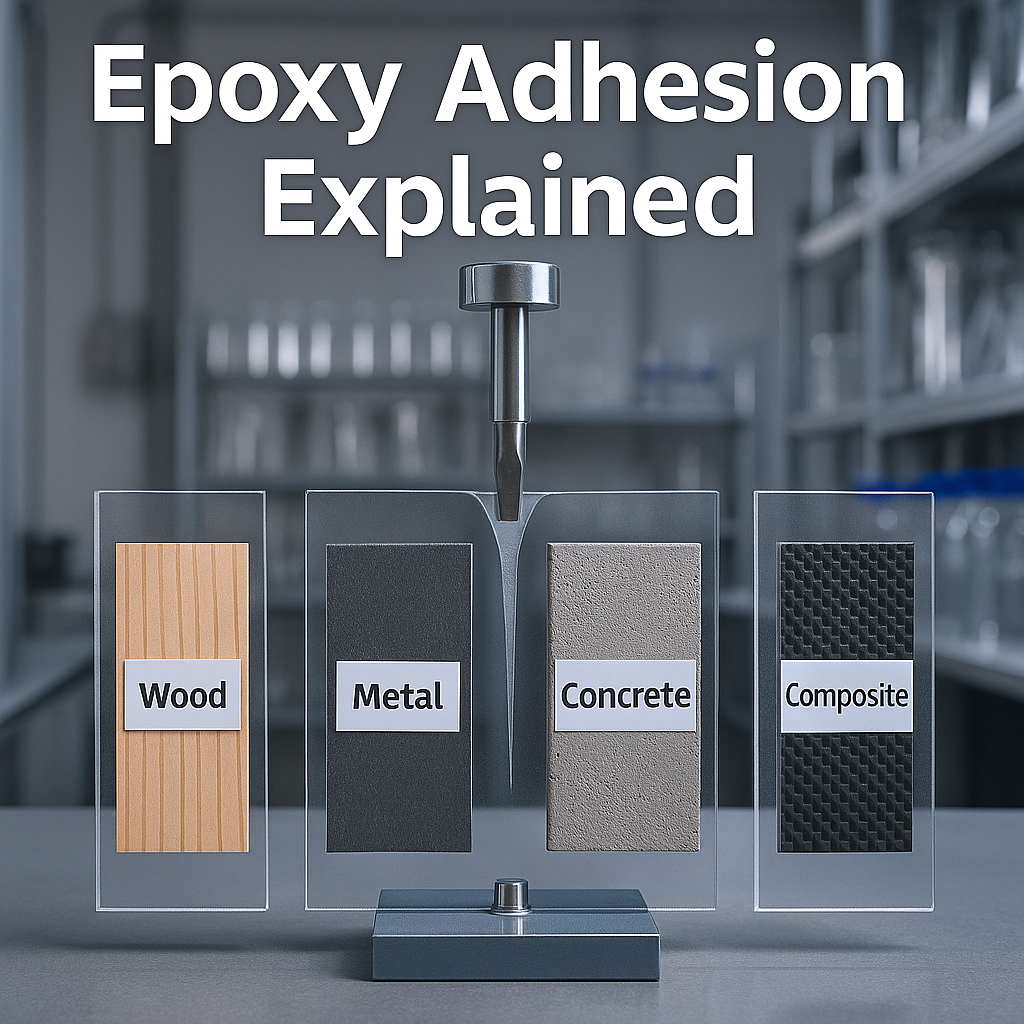

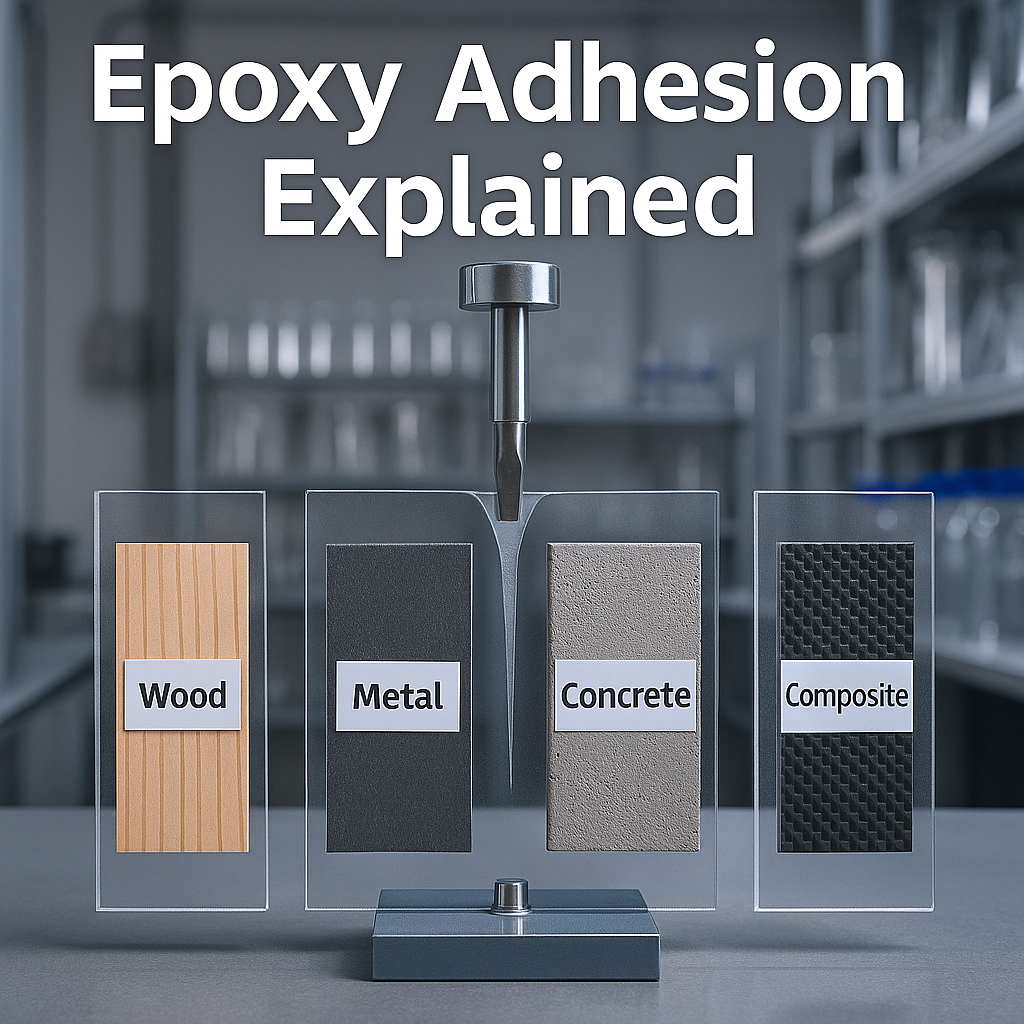

2025-12-05 One of the most valuable properties of epoxy resin is its ability to bond strongly to a wide range of materials. From river tables and artistic creations to industrial flooring and composite structures, epoxy adhesion plays a crucial role in performance and long-term durability.At CNMI Industrial Co

Read More

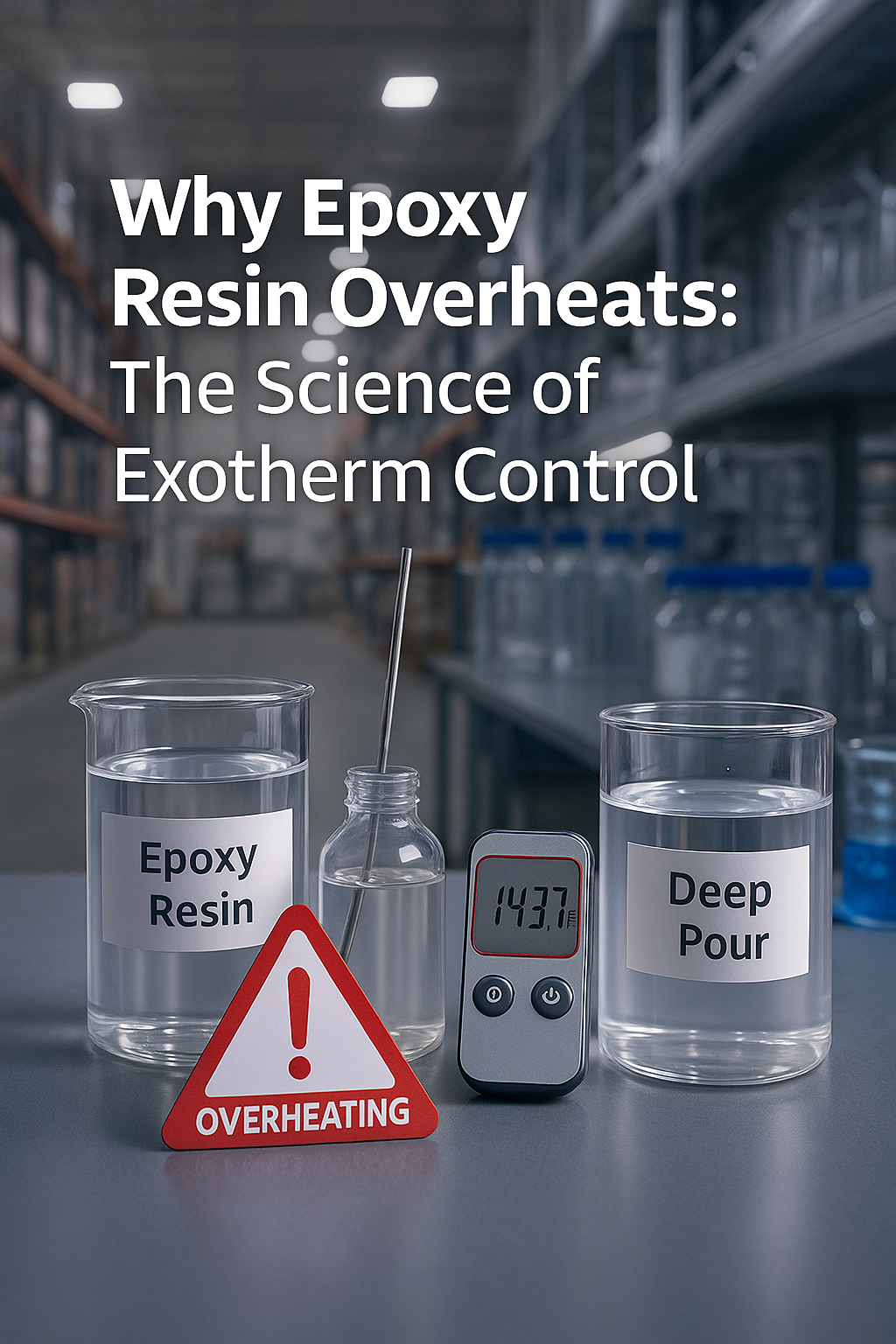

2025-12-04 Epoxy resin generates heat during curing—a natural part of the chemical reaction that transforms liquid components into a solid crosslinked structure. However, excessive heat, known as exotherm, can lead to serious defects, including cracks, discoloration, smoke, warping, and even thermal failure.At

Read More

2025-12-02 Amine blush is one of the most frequently misunderstood surface defects in epoxy resin systems. Although harmless in many cases, blush can cause problems in clarity, adhesion, top-coating, and overall finish quality. It is especially common in cold or humid environments.At CNMI Industrial Corporatio

Read More