S231

CNMI

| Availability: | |

|---|---|

| Quantity: | |

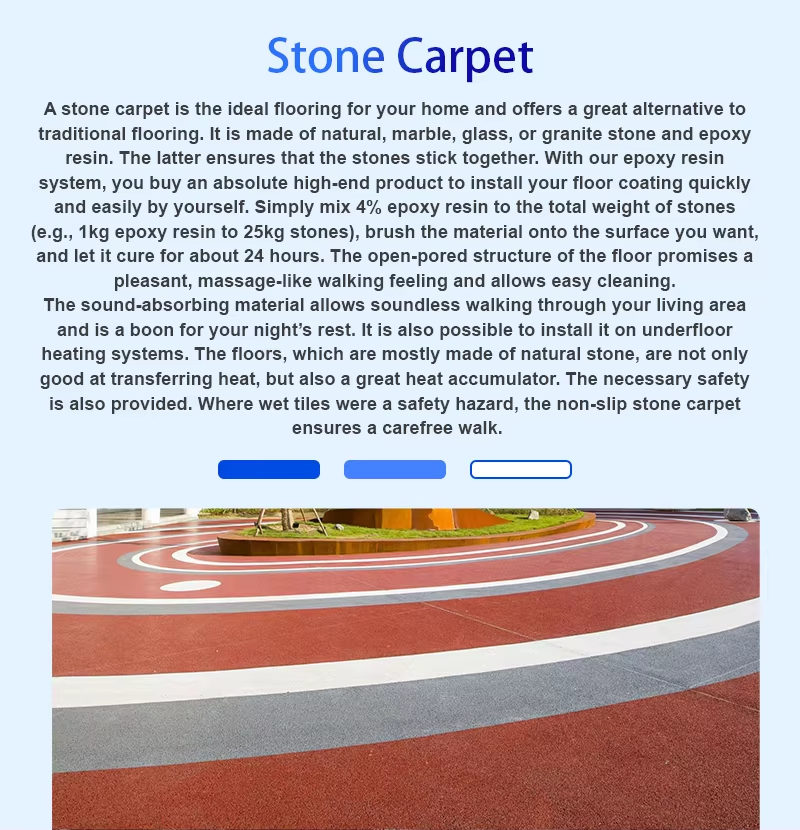

Adhesive stone, also known as adhesive colored stone, adhesive permeable colored stone, adhesive permeable natural stone, and adhesive permeable concrete, is a new type of advanced decorative permeable material. It is made of natural, marble, glass or granite stone and epoxy resin. The latter ensures that the stone is bonded together. With our epoxy resin system, you can purchase absolutely high-end products for quick and easy installation of floor coatings on your own. Just mix 4% epoxy resin with the total weight of the stone (for example, mix 1 kilogram of epoxy resin with 25-30 kilograms of stone), brush the material onto the surface you want, and then let it cure for about 24 hours. The perforated structure of the floor provides a pleasant massage like walking sensation and is easy to clean.

Acoustic materials allow you to walk silently in your living area, which is beneficial for your nighttime rest. It can also be installed on a floor heating system. The floor is mainly made of natural stone, which not only has good heat transfer performance, but also serves as a good heat storage device. It also provides necessary security. In areas where wet tiles pose safety hazards, anti talc carpets can ensure that you walk carefree.

| TECHNICAL PARAMETER | ||

| Environmentallyfiendly adhesive | A component | B component |

| Viscosity pa.s(25°C) | 3000-6000 | 250 |

| Appearance | Transparent liquid | |

| Specific gravity | 1.4-1.6 | 1.02 |

| Use Ratio | 3 | 1 |

| Operation time after mixing | 120-180min | |

| Initial curing time | ~12h | |

| Final curing time | 24h | |

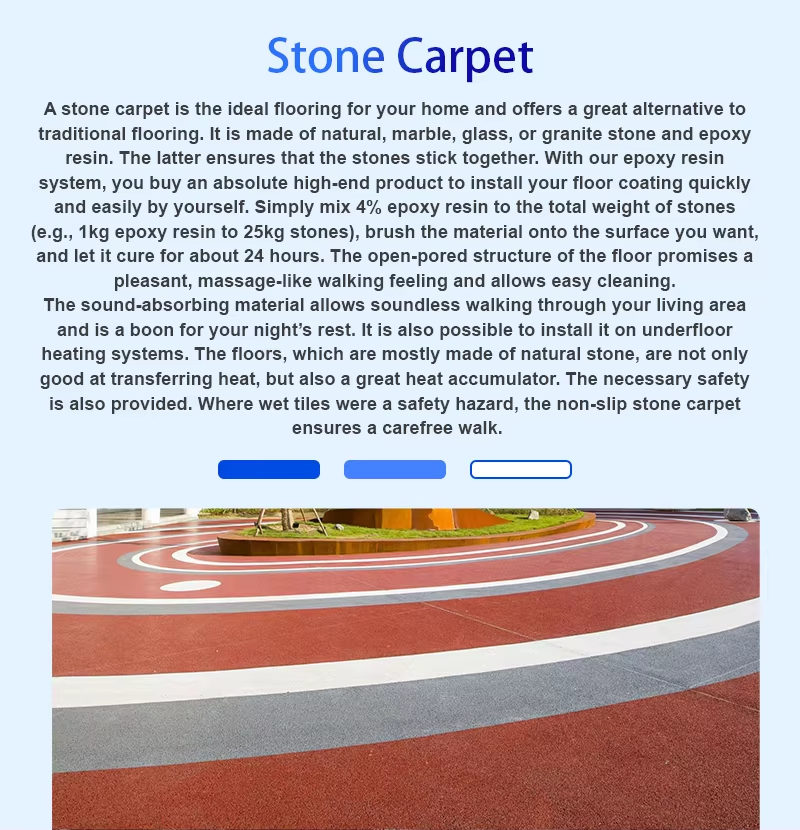

Adhesive stone, also known as adhesive colored stone, adhesive permeable colored stone, adhesive permeable natural stone, and adhesive permeable concrete, is a new type of advanced decorative permeable material. It is made of natural, marble, glass or granite stone and epoxy resin. The latter ensures that the stone is bonded together. With our epoxy resin system, you can purchase absolutely high-end products for quick and easy installation of floor coatings on your own. Just mix 4% epoxy resin with the total weight of the stone (for example, mix 1 kilogram of epoxy resin with 25-30 kilograms of stone), brush the material onto the surface you want, and then let it cure for about 24 hours. The perforated structure of the floor provides a pleasant massage like walking sensation and is easy to clean.

Acoustic materials allow you to walk silently in your living area, which is beneficial for your nighttime rest. It can also be installed on a floor heating system. The floor is mainly made of natural stone, which not only has good heat transfer performance, but also serves as a good heat storage device. It also provides necessary security. In areas where wet tiles pose safety hazards, anti talc carpets can ensure that you walk carefree.

| TECHNICAL PARAMETER | ||

| Environmentallyfiendly adhesive | A component | B component |

| Viscosity pa.s(25°C) | 3000-6000 | 250 |

| Appearance | Transparent liquid | |

| Specific gravity | 1.4-1.6 | 1.02 |

| Use Ratio | 3 | 1 |

| Operation time after mixing | 120-180min | |

| Initial curing time | ~12h | |

| Final curing time | 24h | |